Here are a few terms that will help you understand both the extraction process and components of an extractor. Please post your questions or any other terms you’d like to have defined – your feedback is always appreciated.

Process Terms:

Concentration – the amount of something (in weight) in a given space (volume) – e.g. pounds/gallon, grams/milliliter.

Contamination – any impurity in product – e.g. plant lipid/waxes, plant cell wall debris, water in extracts.

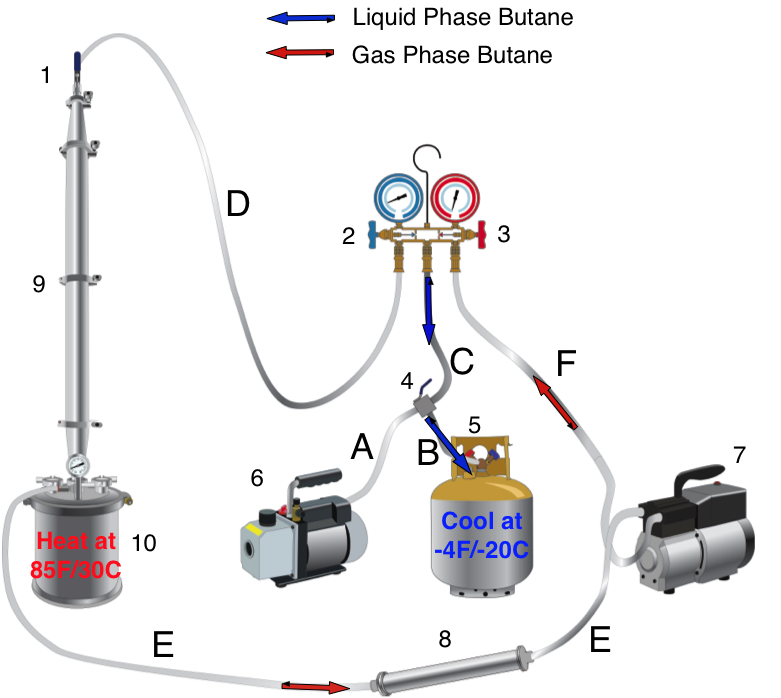

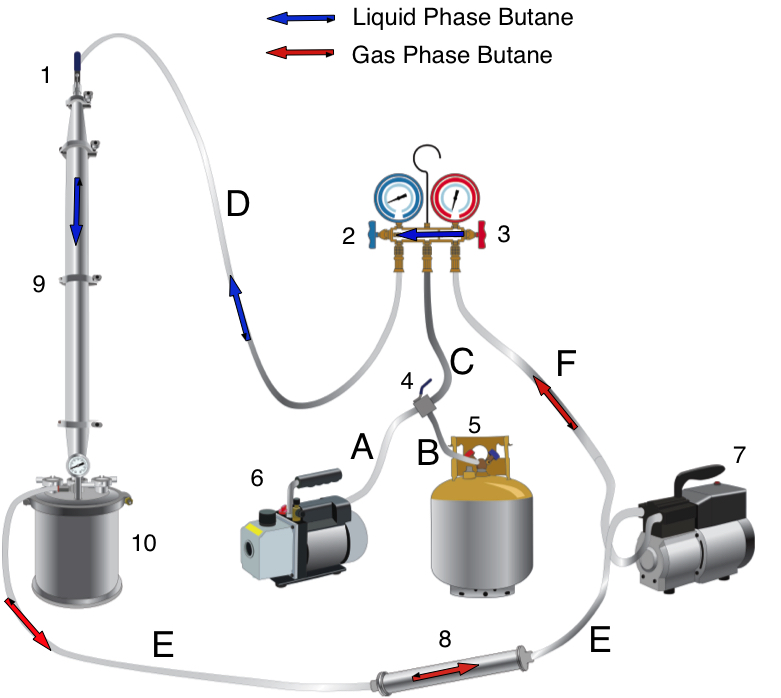

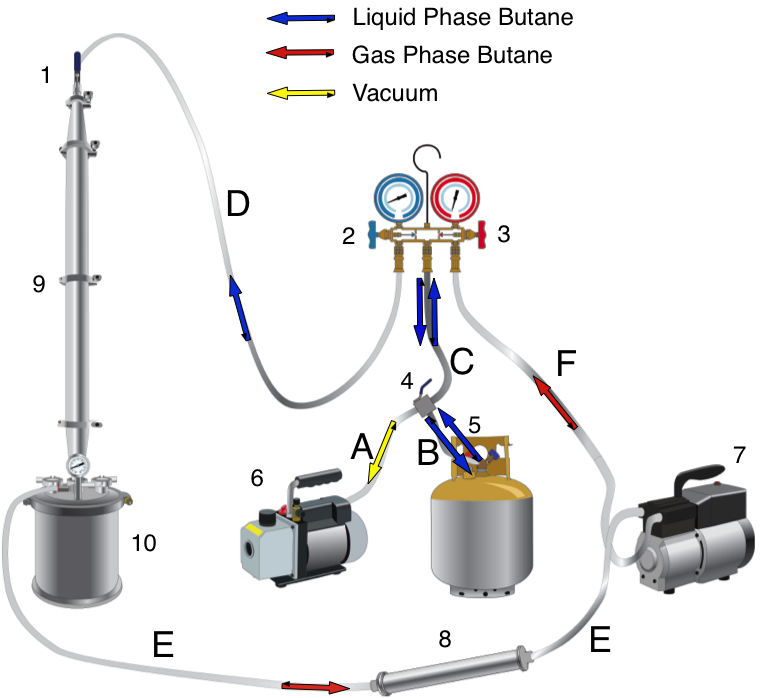

Continuous Shower – a top down shower of butane over a column packed with plant material. The butane is recycled from the extractor collection chamber in the gas phase. It is pumped through the recovery pump (RP) and passes through the condensing coil (CC). The butane changes from the gas phase to liquid phase, and passes through the recovery manifold (RM), and back through the top of the column. The plant material is then “continuously” showered with cold liquid butane. This strips the plant material of all its butane soluble molecules – i.e. cannabinoids, terpenes, and plant lipids/waxes

Cooling Bath – a mixture of ice and water or dry ice and ethanol that is used to cool down extractor components like the recovery cylinder (RC)

Fractions – different grades of trichomes/hash depending on amount of plant material contamination.

Gas Phase – butane is a gas

“Hg or inches Hg – signifies the vacuum pressure of the system in “inches” of mercury.Maximum vacuum is 29”Hg while zero vacuum is 0”Hg. It’s a way of describing negative pressure, just like MPa (metric system measurement – mega Pascals), KPSI (standard/US system measurement – thousands of Pounds Per Square Inch), or bar/atm (metric measurement – the pressure in terms of the number of atmospheres)

Liquid Phase – butane is a liquid

Risk based approach – examining the inherent risks involved in a process and eliminating risks to improve the product safety or process safety.

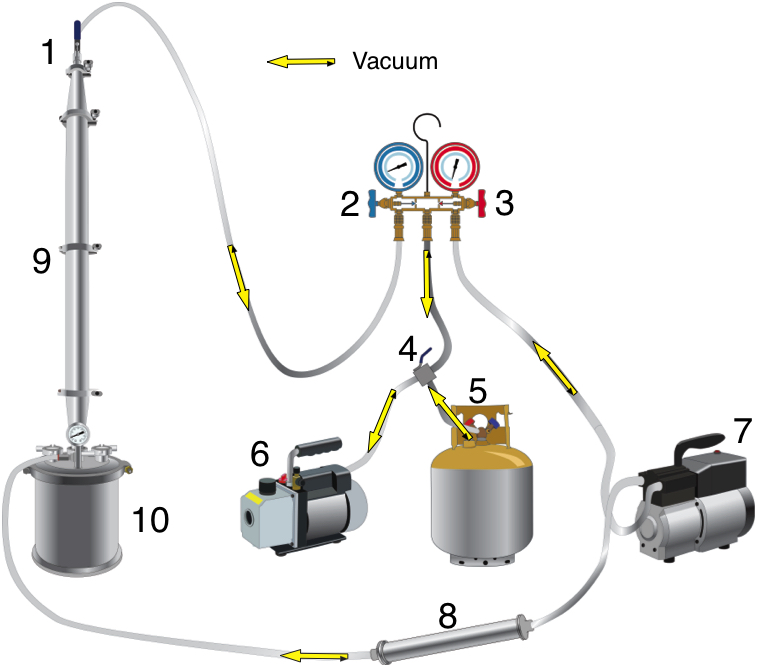

Vacuum – the vacuuming step is the first step in preparing the system for extraction. It is necessary to vacuum the extractor for two reasons. First it creates negative pressure that pulls the butane into the extractor. Second, it removes the majority of the atmospheric oxygen in order to prevent conditions where butane can ignite – remember that butane needs oxygen in order to combust.

Winterization – the process that removes plant lipids/waxes from an extract.

Component Terms:

Condensing/cooling Coil (CC) – a stainless steel coiled tube that acts as a heat exchanger. As butane gas passes into it, it cools down the gas and it changes over to the liquid phase – this is called a phase change of matter.

Dewaxing Column – a column that has cooling capabilities with dry ice and ethanol. It typically requires a 1 hour soak time to achieve dewaxing, although the process is often incomplete if not done under the proper conditions.

Gaskets – Buna, Viton, or PTFE “rings” that are placed between two sanitary fittings

High Pressure Side Recovery Manifold – the red side gauge and valve that opens and closes to allow gaseous butane to flow in to the manifold. The gas can be condensed into the liquid phase by maintaining a pressure of 100PSI and can be diverted back out the low pressure side or back into the recovery cylinder.

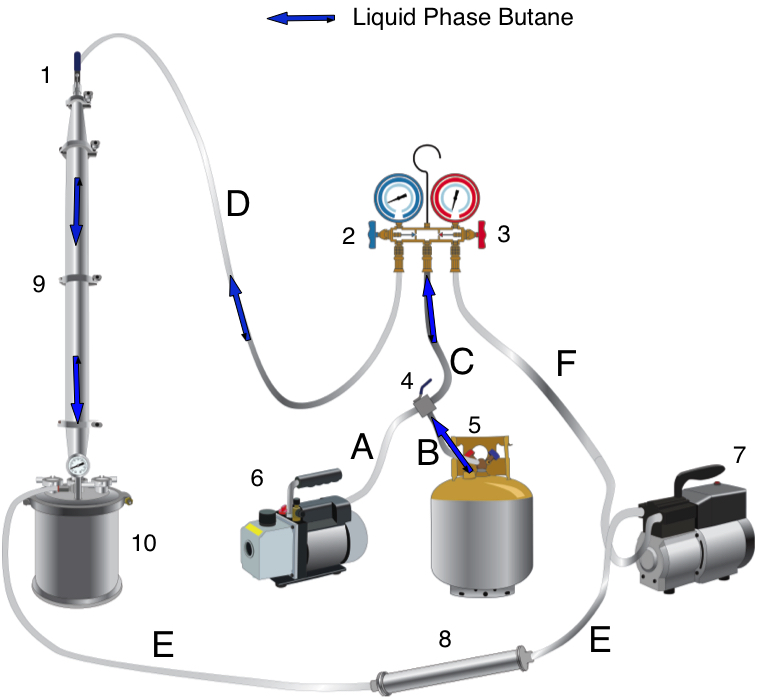

Low Pressure Side Recovery Manifold – the blue side gauge and valve, that opens and closes to allow liquid butane to flow into the extraction column.

Recovery Cylinder Liquid Side Valve – the valve (either blue or red) that has “LIQUID” printed on it. This valve opens up the extraction system to liquid butane. Different manufacturers have different conventions, so don’t assume you have the liquid side just because it’s blue.

Recovery Cylinder Liquid Straw – the tube that is attached to the recovery cylinder liquid side needle valve. The straw allows liquid butane to flow into through the valve into the extraction system.

Sanitary Fittings – individual pieces that make up the stainless steel columns and spools. Pieced together, they make the extraction column and extractor collection chamber. Sanitary fittings are held together by high-pressure triclamps

As always, if you have any questions please post them in the comments section. Your questions and time are valuable and we will make every attempt to help you through your process.