When the extractor has been properly shut down, it’s time to disassemble it and reveal the cannabinoid alchemy you’ve performed, turning solid green plant matter into a concentrated liquid gold $)

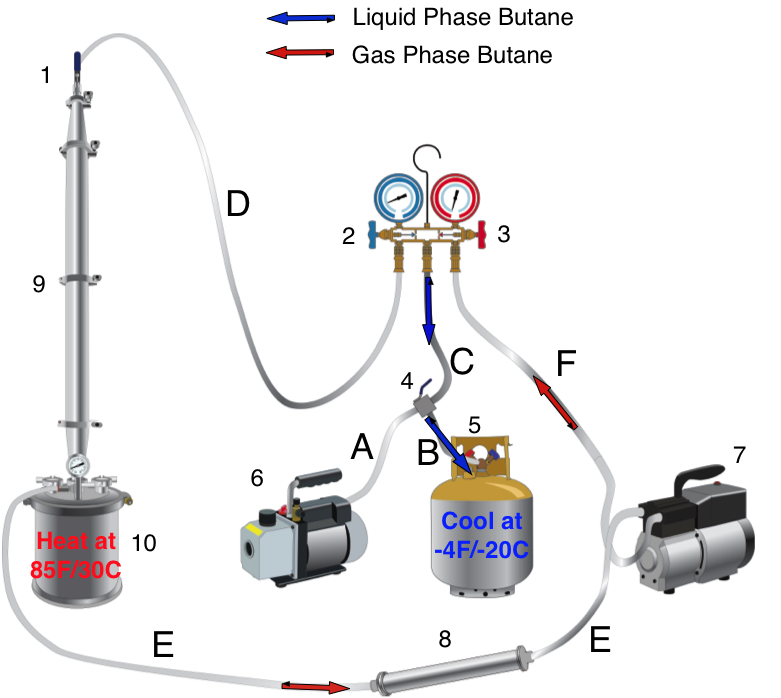

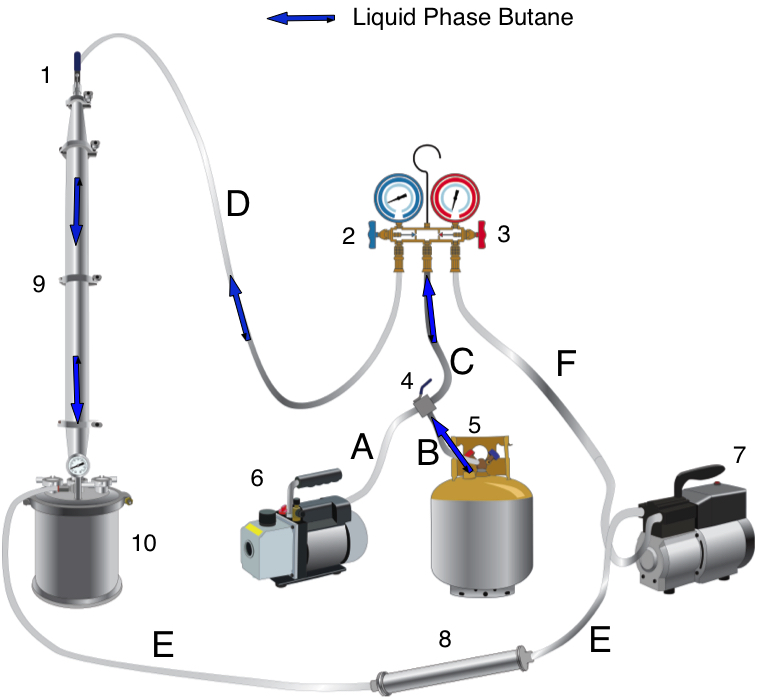

| Step 7 – Extractor Disassembly – remove stainless steel hose (D) from extractor column valve (1) | ||||

| Component # | Component Name | Abbreviation | Open/On | Closed/Off |

| 1 | Extraction Column Valve | ECV | x | |

| 2 | Low Pressure Recovery Manifold | RM2 | x | |

| 3 | High Pressure Recovery Manifold | RM3 | x | |

| 4 | Purge Port | PP | x | |

| 5 | Recovery Cylinder | RC | x | |

| 6 | Vacuum Pump | VP | x | |

| 7 | Recovery Pump | RP | x | |

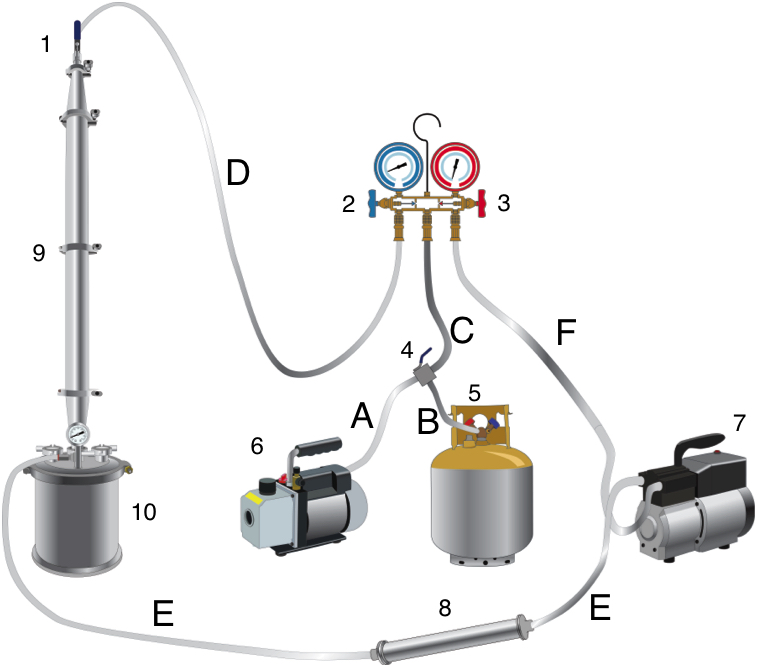

| Step 7.1 – Extractor Disassembly – open extractor column valve (1) to allow air to enter extractor | ||||

| Component # | Component Name | Abbreviation | Open/On | Closed/Off |

| 1 | Extraction Column Valve | ECV | x | |

| 2 | Low Pressure Recovery Manifold | RM2 | x | |

| 3 | High Pressure Recovery Manifold | RM3 | x | |

| 4 | Purge Port | PP | x | |

| 5 | Recovery Cylinder | RC | x | |

| 6 | Vacuum Pump | VP | x | |

| 7 | Recovery Pump | RP | x | |

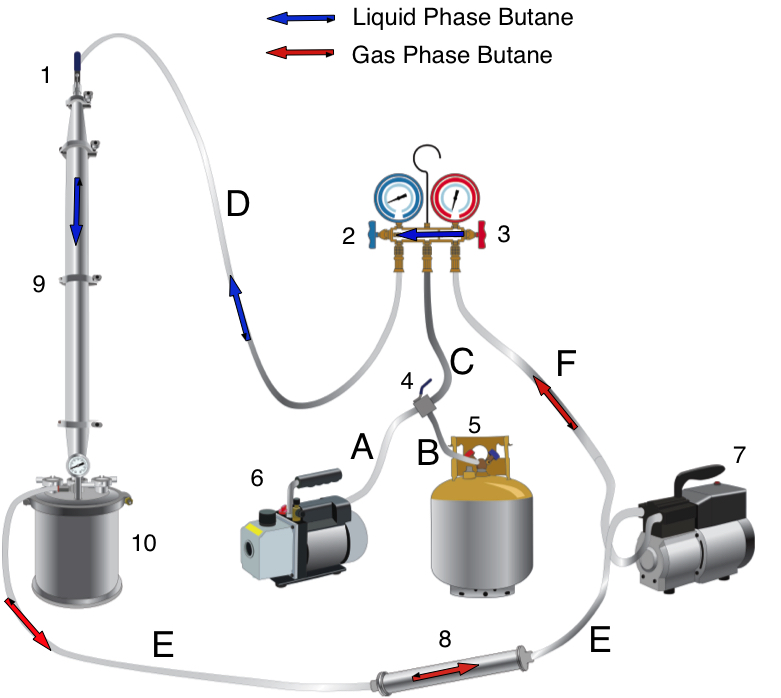

| Step 7.2 – Extractor Disassembly – remove extraction column (11) | ||||

| Component # | Component Name | Abbreviation | Open/On | Closed/Off |

| 1 | Extraction Column Valve | ECV | x | |

| 2 | Low Pressure Recovery Manifold | RM2 | x | |

| 3 | High Pressure Recovery Manifold | RM3 | x | |

| 4 | Purge Port | PP | x | |

| 5 | Recovery Cylinder | RC | x | |

| 6 | Vacuum Pump | VP | x | |

| 7 | Recovery Pump | RP | x | |

| Step 7.3 – Extractor Disassembly – remove extractor base from extractor collection vessel (12) | ||||

| Component # | Component Name | Abbreviation | Open/On | Closed/Off |

| 1 | Extraction Column Valve | ECV | x | |

| 2 | Low Pressure Recovery Manifold | RM2 | x | |

| 3 | High Pressure Recovery Manifold | RM3 | x | |

| 4 | Purge Port | PP | x | |

| 5 | Recovery Cylinder | RC | x | |

| 6 | Vacuum Pump | VP | x | |

| 7 | Recovery Pump | RP | x | |

As always, if you have any questions please post them in the comments section. Your questions and time are valuable and we will make every attempt to help you through your process.