Setting up your recovery pump is a simple process on most extractors. You will likely have a 3/8” recovery hose connected to the lid of your collection chamber, where the gaseous butane is pulled through to the recovery pump (low pressure side) and pumps out to the high pressure side to be dumped into the recovery cylinder.

A real world example by an awesome company.

There is a very good example of this setup on the market by Precision Extractors. If you pull up their website and take a look at the back of the extractor, you’ll see there is a column that is plumbed and placed behind the secondary recovery cylinder (on the right). That column is filled with 3A molecular sieves and is plumbed to the primary filling cylinder (on the left).

Their system works by pumping butane from the primary filling cylinder into the primary extraction column. After passing through the primary extraction column, it passes into the dewaxing column. The butane is evaporated off by heating the collection chamber and the negative pressure from the pump, pumping the butane into the recovery chamber.

From there, the butane passes through the pump in the gas phase to the 3A molecular sieve column. The butane gas passes out of the 3A molecular sieve column and is pumped into the primary filling cylinder where it condenses into the liquid phase due to the cold temperatures and higher pressure.

Although Precision Extractors have this set up natively on the PX1, there’s no reason a similar system can’t work with your current extractor. The explanation follows below.

Setting up your current extractor for in-line dehydration.

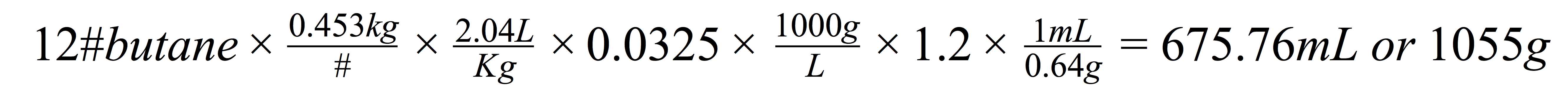

This is a simple system. It really just requires an additional column with end plates, an inline filter, and one additional stainless steel braided hose. Read up on the post about dehydrating your butane. On average, 1000g or 1Kg or 3A molecular sieves will be have enough capacity to dry all the butane you could use in a week. Use an appropriately sized column and pack it with the sieves. Connect a filter plate and a filter at the bottom of the column, and you’re nearly there.

Connect your 3A molecular sieve column (8) between the collection chamber (10) and the low pressure side of the recovery pump (7). While you may say that in-line filter driers can do the job, they’re not really up to the task when you do the desiccant math. This is a step that is better done with more desiccant than less. This is a simple improvement on what most people already do. You can certainly use an inline filter drier, but this ensures an efficacious dehydration.

Dehydration is an ongoing process.

While putting a column of molecular sieves inline is an improvement, it is only part of the process. It is very important that the molecular sieves are dried out after a day’s extractions. The nice part of this setup is that you can easily remove the molecular sieves from the column. That’s important because you need to dehydrate your sieves after you use them so they’re ready to dehydrate your butane – the beauty of molecular sieves is that they are re-useable.

Once you’ve removed your sieves, pour them out into a pyrex dish. You can then put them into your vacuum chamber, apply heat and vacuum, and have fully recharged/dehydrated desiccant ready for use in the morning. This is a standard process in the pharmaceutical industry where drug substances must be kept free of humidity while in storage, and the molecular sieves are periodically recharged.

Conclusion.

For the price, you can’t miss the beat on dehydrating your butane. Not only does the dehydration improve your yields, it also helps save the seals of your pump that do not react well with water. Given those two improvements, the small investment of molecular sieves in-line from your extraction chamber to the low pressure side of your pump will pay itself back quickly.

As always, if you have any questions please post them in the comments section. Your questions and time are valuable and we will make every attempt to help you through your process.