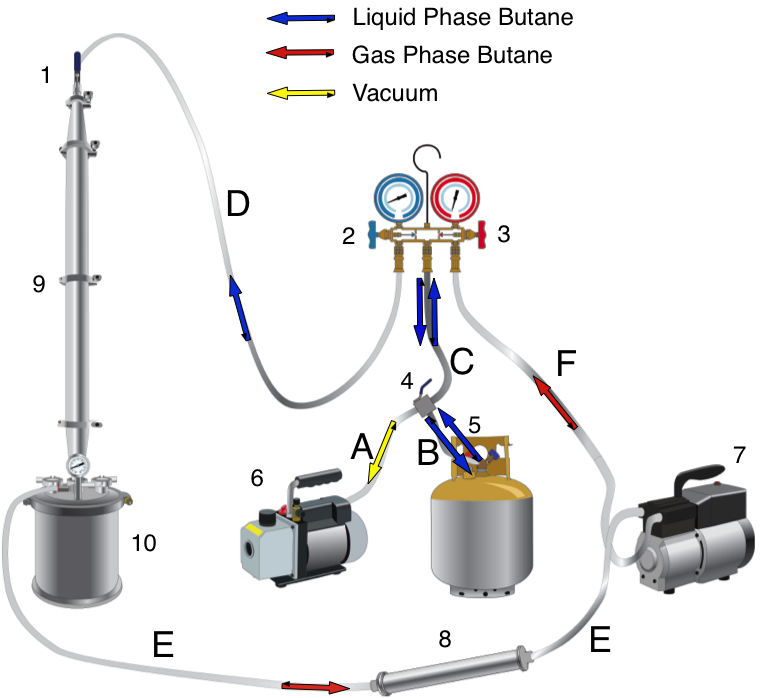

It is essential to understand the pathways of the different braided stainless steel lines lead to in order to understand the flow of the butane.

The best suggestion to learn this, is to visualize it. If you can picture it in your head, you can perform it on the extractor. By the time you’re done with this series of posts, you should be able to safely operate an extractor in both your mind as well as in reality.

As will be explained in a later post, the high pressure side recovery manifold valve (3) is closed just far enough to keep ~100PSI. By keeping 100PSI, the gas phase butane is liquified because the pressure. That liquid butane can be cycled back through (D) into the extractor or it can pass through (C) and (B) back into the recovery cylinder.

| Stainless Steel hoses | |

| A | 6 to 4 – vacuum pump to purge port |

| B | 5 to 4 – recovery cylinder to purge port |

| C | 4 to 2/3 – purge port to recovery manifold |

| D | 2 to 1 – low pressure side recovery manifold to extraction column valve |

| E | 10 to 7 – extraction collection chamber to recovery pump |

| F | 7 to 3 – recovery pump to high pressure side recovery manifold |

As always, if you have any questions please post them in the comments section. Your questions and time are valuable and we will make every attempt to help you through your process.