CBDecomissioning THC

There are reported methods and patents for converting CBD into THC and for maximizing THC production, but what about the other way around? Could there be a way to convert psychoactive THC into non-psychoactive CBD?

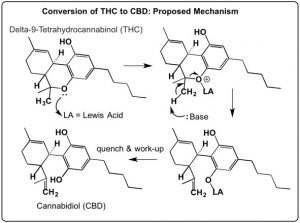

Mechanisms for opening THC.

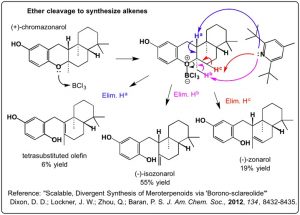

Looking at the structures of these cannabinoids, one can imagine a plausible mechanism to open up THC’s ether ring to the phenol of CBD. Fortunately, this kind of chemistry has been done before, and there are examples in the literature. Many molecules in nature have similar structures to THC and CBD because they are all part of a larger family of molecules called terpenoids, made from the same biochemical building blocks. So although the conversion of THC to CBD has not actually been reported, to my knowledge, there are conditions in the literature that are directly applicable to this transformation. Specifically, in 2012, the Baran synthesis group at the Scripps Research Institute in La Jolla, CA published a paper in JACS, where they synthesized diverse meroterpenoids from a boron-containing scaffold derived from sclareolide, a fragrant lactone found in sage. Their divergent and scalable synthesis allowed access to a wide variety of structures from nature, and also some synthetic analogues. Among the many reactions that they report, one of them is directly analogous to the conversion of THC to CBD: the conversion of chromazonarol to isozonarol.

Scaling up.

Usually, reactions done on a small scale (15 mg of starting material was used) are not directly applicable to an industrial scale without substantial effort. Since it was a final step, they did not need to optimize the reaction to be environmentally friendly or cost effective, as it was not a priority for the broad goals of this project. The conditions that they report (dichloromethane as solvent, -78 degree C temperature, BCl3 as a Lewis acid, 2,6-di-tert-butyl-4-methylpyridine as a bulky, more selective base), might not be directly scalable, especially for those with limited experience in synthetic chemistry.

Semisynthesis.

The field of natural product synthesis specializes in these types of transformations, to be able to convert one structure to another in order to access a natural product target either from simple commodity chemicals (total synthesis) or another natural product (semisynthesis). The conversion of THC to CBD would be classified as semisynthesis, since the starting material is another natural product – THC. Semisyntheses can have an advantage that the starting material is often similar in structure to the product, thus requiring fewer steps. However, some molecular targets cannot easily be accessed by semisynthesis, but their unique structure can be made from scratch, essentially, using organic chemistry methods to construct the scaffolds from chemical feedstocks. Both total synthesis and semisynthesis are used industrially for different purposes, and both strategies incorporate the same organic chemistry principles when designing a route.

The thought process.

As an important and necessary part of synthesis, reaction conditions are optimized using small amounts before scaling up; hypothesis-driven trial-and-error, or in some cases, high-throughput screening can be used to develop a more robust and ideal process. All factors of this reaction have the potential to be changed: the solvent, the Lewis acid, and the base. I would recommend, first, for a chemist to do this reaction with THC, using the same scale, reagents, and conditions as those in the paper. This would require access to a fume hood, to avoid exposure to the toxic reagents. After getting a sense of this, for example find out: what is the yield of CBD? How much recovered THC? Is any of the tetra substituted olefin formed? Then, the reaction conditions can be altered (time, temperature, equivalents) to increase yield, and a different solvent, Lewis acid, or base can be swapped to reduce toxicity and cost. This reaction optimization process may sound complex, and will definitely not be an easy problem to solve, but I know from experience, from a chemistry standpoint, this problem is solvable. With careful observation, organic chemistry intuition, and perseverance, there is no reason we cannot develop a method for converting THC into CBD, essentially “de-commissioning” a Schedule I substance.

Contact Us.

Orion GMP Solutions is a Pharmaceutical Process Engineering firm based out of Denver Colorado. We specialize in the implementation and auditing of GMP Cannabis Manufacturers to assist them in reaching international markets. If you would like to get more information, please send us an email at info@oriongmp.com.

This content was written and supported by Orion GMP Solutions.